The cut lines are kept close to the bench to provide as much support as possible.

Annealing aluminum sheet.

The severely cold working or full hard condition h18 aluminium temper is usually obtained with cold working equal to about 75 reduction in area the h19 temper identifies products with substantially higher strengths and greater.

6xxx magnesium silicon alloy.

Here the profile is being cut with a metal cutting blade in a jig saw.

Also as aluminum comes from the mill it develops a coating aluminum oxide as it cools.

The change increases in magnitude with increasing temperature.

Annealing is used for steel however other metals including copper aluminum and brass can be subject to a process called solution annealed.

This should anneal the 6061 t6 or other t into a t 0 material.

The sheet was worked hard before annealing.

If necessary an excellent cutting oil for aluminium is wd40 or a similar light spray oil.

The torch soot process is the method whereby the workman sets the torch to either pure acetylene or an acetylene rich condition and coats the panel with the.

This is one of the most common kinds of aluminum especially 6061 and it anneals.

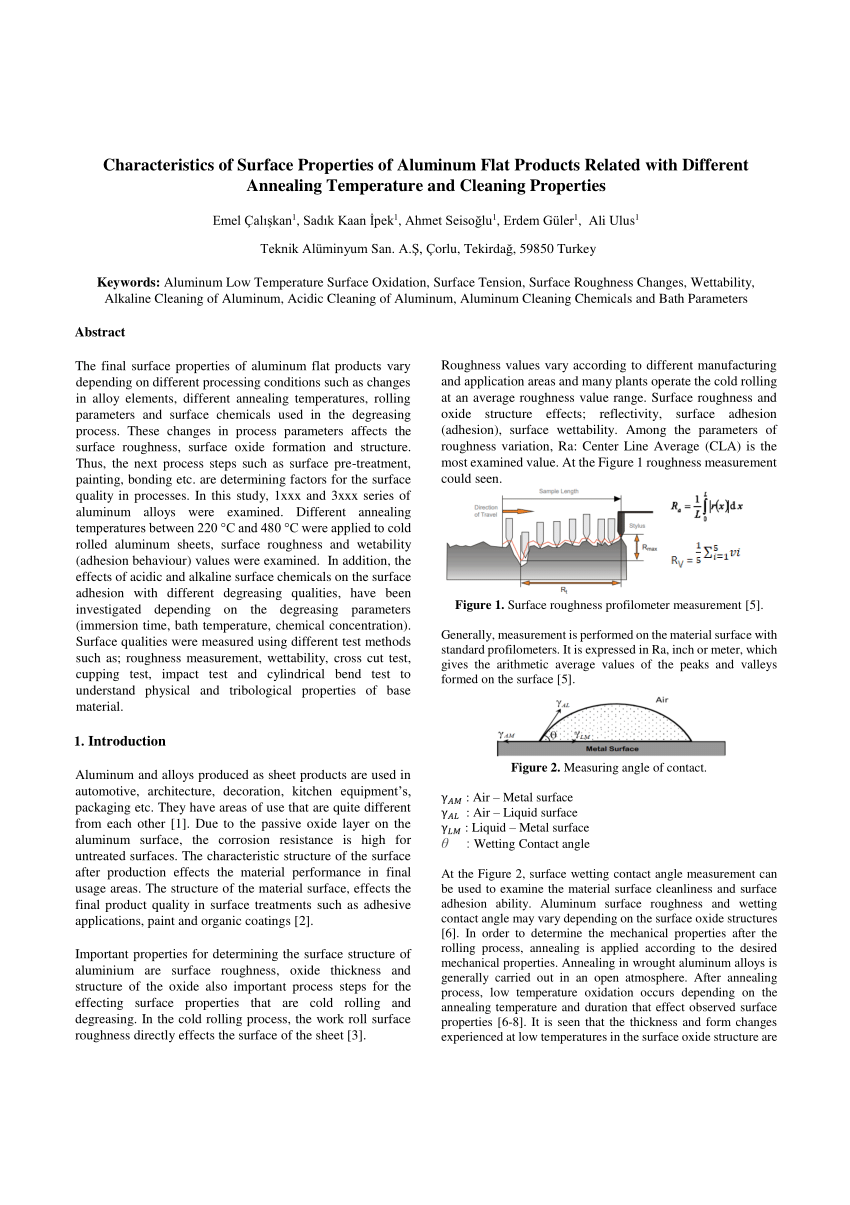

Isothermal annealing curves for 1100 h18 sheet.

Recovery annealing is also accompanied by changes in other properties of cold worked aluminum.

Annealing of aluminum and aluminum alloys.

Generally some property change can be detected at temperatures as low as 200 to 250 f 90 c to 120 c.

This is common to see in sheet metal form and it s malleable stuff.

Annealing works fine for complicated and deep forming but to form simpler stuff it s unlikely that you ll need it.

By annealing the metal beforehand cold working can take place without any risk of cracking as annealing releases mechanical stresses produced during machining or grinding.

In metallurgy and materials science annealing is a heat treatment that alters the physical and sometimes chemical properties of a material to increase its ductility and reduce its hardness making it more workable it involves heating a material above its recrystallization temperature maintaining a suitable temperature for an appropriate amount of time and then cooling.

The wooden blocks prevent damage to the sheet.

This makes the aluminum about as bendable as it can get.